Array

(

[0] =>

)

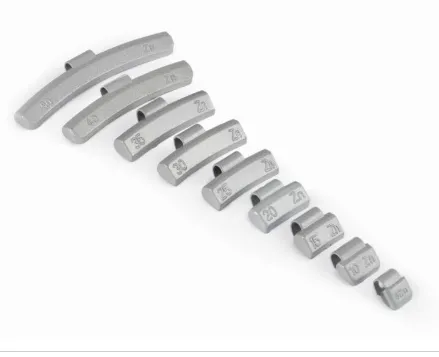

Stud-on weights for aluminum rims with a weight of 5 grams , made of zinc (ZN) and protected with a gray polymer protective coating. The weights are mounted on the rim by pressing them onto the rim using special weight pliers. Stable seating on the rim is guaranteed by a precisely selected spring . The weights have an elegant shape , thanks to which they adhere perfectly to the edge of the rim flange . The package contains 100 weights . ZN weights meet the legal requirements of Directive 2005/673/EC, which is why zinc weights are an ideal alternative to stud weights made of lead.

Weights offered are guarantee of:

Production quality

Studded, zinc and coated weights are the highest quality product. For the production of weights, high-quality raw material is used, selected according to rigorous parameters. To ensure easy assembly, the weights are precision cast. Thanks to this, the weights have a perfect shape, which makes them perfectly fit the steel rims, and their assembly is quick and efficient.

Durability

The weights are made of zinc and are additionally covered with a gray protective coating, which provides protection against corrosion and other harmful weather conditions. A strong spring (clip) guarantees a durable and stable mounting of the weight on the rim.

Perfect fit

In order to meet even the greatest requirements and maximally improve and shorten the work of our customers, the offered product has a very precise casting, thanks to which it fits perfectly with the aluminum rim. Its optimal shape and size enables trouble-free mounting on the rim. In addition, a stably mounted spring (clip) guarantees permanent placement of the weight. After mounting the weight, it cannot be moved from the designated place or fall off while driving.

Versatility

The shape, size and weight allow for mounting on aluminum rims wheels of passenger cars, as well as off-road vehicles and vans. Their universality of use allows to significantly reduce the number of weights in the workshop. One product for use on different types of aluminum rims. The special shape of the weight enables universal use on vehicle rims up to 3.5 t.

Precise balancing

We offer the highest quality products. Each batch of weights is checked in our laboratory according to strictly defined standards. We have a strictly defined accuracy for the weight of each grammage. In addition, we attach great importance to the quality of the raw material from which the weights are made. All this allows you to maintain the appropriate weight parameters of the weight, which greatly facilitates balancing.

Destiny:

Clip-on weights are designed to correct the balancing of wheels, which is done by using a load of appropriate weight. This procedure allows you to correct the weight of the wheel in an easy and quick way.

Application:

Balancing the wheels of passenger cars, SUVs and vans mounted on aluminum rims.

Assembly method:

Remove the old clip-on weights before installing the weight. To avoid damaging the rim, use a suitable tool for removal and installation. We select the grammage based on the balancer's indications. Before installation, place a weight next to the rim flange to check the shape of the rim flange. Then place the weight in the place indicated by the balancer. Before hitting the weight, make sure that the spring is properly contacting the rim flange. Once the weight is in place, tap the spring twice with a suitable tool. It is worth remembering that a greater number of hits may damage the protective coating of the weight. Verification of seating is required after installation. To do this, grab the weight with two fingers and try to move it.